Maeving electric motorcycle:

No gears. No petrol. No smell. No noise.

The brief

Seb and Will came to us with a very simple brief. They wanted a retro style electric motor bike for urban living. The bike needed a top speed of 45–50mph, could go 50 miles without recharging, and have a removable battery to recharge at work or at home. A designer's dream. We probed as to why a start-up idea like this would have traction and what the USP was. They showed the comparison of sales of electric bikes across Europe and it was clear that the UK was far behind the curve. This was a growing market and we were as convinced as they were that if we could produce a works-like-looks-like prototype, they would get funding.

The bang

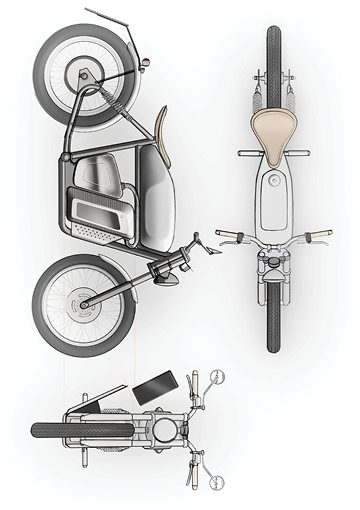

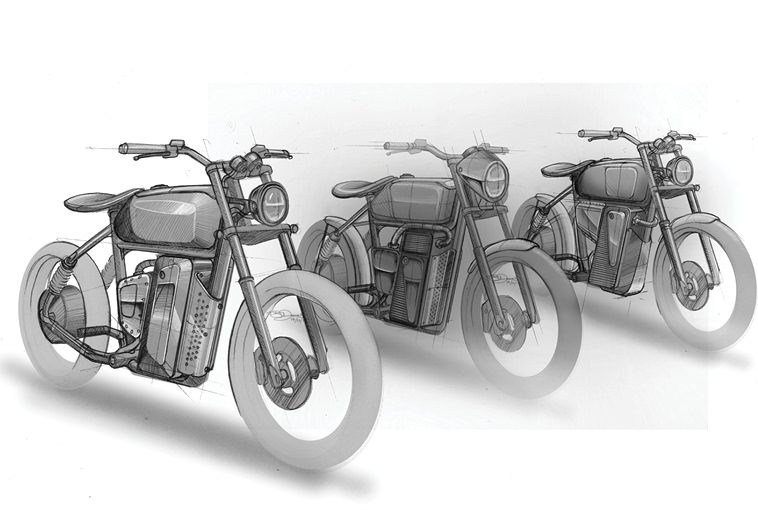

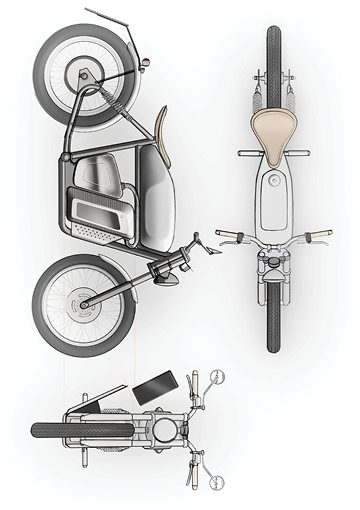

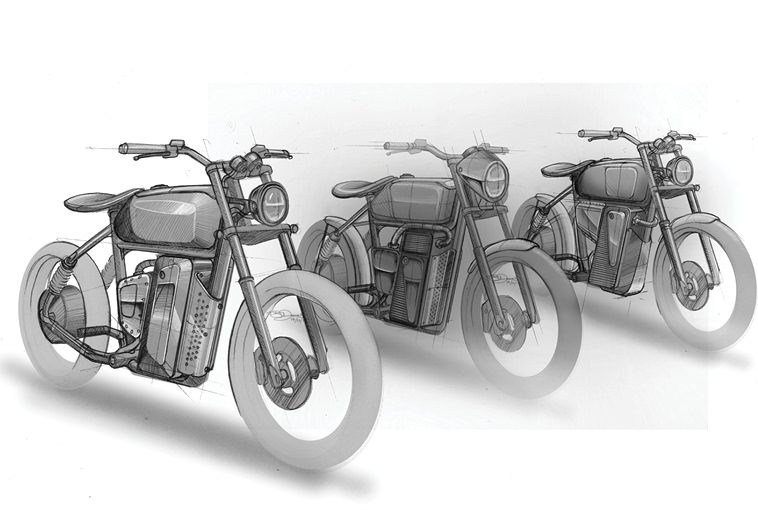

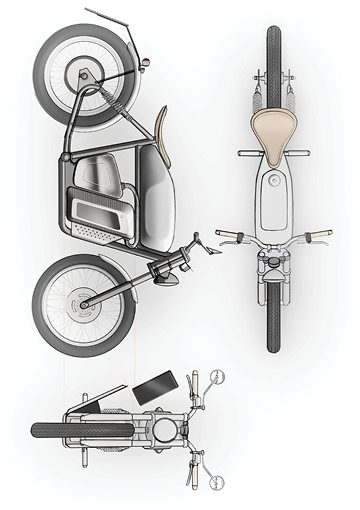

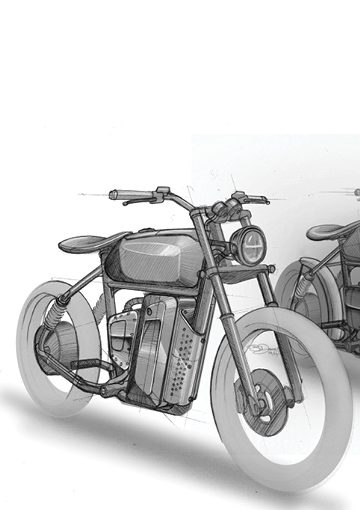

To begin with, this was a straight industrial design project. We produced several sketches and ideas for sign off, and then went straight into welding together a rolling rig. Even sitting on the bent tube assembly, you could feel the riding position. Once everyone was happy, the pivotable point in the project was when we had a working looks-like prototype we could ride. The prototype was a mixture of welded assemblies, off the shelf parts and the main housings being 3d printed and CNC. It took a few months in the middle of Covid for Seb and Will to secure funding and we then worked with their excellent engineering team to take the product into manufacture.

The result

We are really pleased for our clients who, in two years, took an idea to market, and have a successful business employing a team manufacturing in the UK. This project epitomises our B Corp mission; to design products that are commercially viable, whilst being technically feasible as well as being socially and environmentally responsible.

"If it were not for Bang Creations’ agile way of working and lean company structure we would have been unlikely to get the project off the ground; in so far as Bang’s investment in us, and the speed of delivery, could not have been matched by the two automotive design giants we were courting simultaneously – and the quality of engineering could not have been matched by a custom bike designer/builder; given their lack of DFA/DFM consideration." Seb Inglis-Jones Co-Founder Maeving bikes.

Maeving electric motorcycle:

No gears. No petrol. No smell. No noise.

The brief

Seb and Will came to us with a very simple brief. They wanted a retro style electric motor bike for urban living. The bike needed a top speed of 45–50mph, could go 50 miles without recharging, and have a removable battery to recharge at work or at home. A designer's dream. We probed as to why a start-up idea like this would have traction and what the USP was. They showed the comparison of sales of electric bikes across Europe and it was clear that the UK was far behind the curve. This was a growing market and we were as convinced as they were that if we could produce a works-like-looks-like prototype, they would get funding.

The bang

To begin with, this was a straight industrial design project. We produced several sketches and ideas for sign off, and then went straight into welding together a rolling rig. Even sitting on the bent tube assembly, you could feel the riding position. Once everyone was happy, the pivotable point in the project was when we had a working looks-like prototype we could ride. The prototype was a mixture of welded assemblies, off the shelf parts and the main housings being 3d printed and CNC. It took a few months in the middle of Covid for Seb and Will to secure funding and we then worked with their excellent engineering team to take the product into manufacture.

The result

We are really pleased for our clients who, in two years, took an idea to market, and have a successful business employing a team manufacturing in the UK. This project epitomises our B Corp mission; to design products that are commercially viable, whilst being technically feasible as well as being socially and environmentally responsible.

"If it were not for Bang Creations’ agile way of working and lean company structure we would have been unlikely to get the project off the ground; in so far as Bang’s investment in us, and the speed of delivery, could not have been matched by the two automotive design giants we were courting simultaneously – and the quality of engineering could not have been matched by a custom bike designer/builder; given their lack of DFA/DFM consideration." Seb Inglis-Jones Co-Founder Maeving bikes.

Maeving electric motorcycle:

No gears. No petrol. No smell. No noise.

The brief

Seb and Will came to us with a very simple brief. They wanted a retro style electric motor bike for urban living. The bike needed a top speed of 45–50mph, could go 50 miles without recharging, and have a removable battery to recharge at work or at home. A designer's dream. We probed as to why a start-up idea like this would have traction and what the USP was. They showed the comparison of sales of electric bikes across Europe and it was clear that the UK was far behind the curve. This was a growing market and we were as convinced as they were that if we could produce a works-like-looks-like prototype, they would get funding.

The bang

To begin with, this was a straight industrial design project. We produced several sketches and ideas for sign off, and then went straight into welding together a rolling rig. Even sitting on the bent tube assembly, you could feel the riding position. Once everyone was happy, the pivotable point in the project was when we had a working looks-like prototype we could ride. The prototype was a mixture of welded assemblies, off the shelf parts and the main housings being 3d printed and CNC. It took a few months in the middle of Covid for Seb and Will to secure funding and we then worked with their excellent engineering team to take the product into manufacture.

The result

We are really pleased for our clients who, in two years, took an idea to market, and have a successful business employing a team manufacturing in the UK. This project epitomises our B Corp mission; to design products that are commercially viable, whilst being technically feasible as well as being socially and environmentally responsible.

"If it were not for Bang Creations’ agile way of working and lean company structure we would have been unlikely to get the project off the ground; in so far as Bang’s investment in us, and the speed of delivery, could not have been matched by the two automotive design giants we were courting simultaneously – and the quality of engineering could not have been matched by a custom bike designer/builder; given their lack of DFA/DFM consideration." Seb Inglis-Jones Co-Founder Maeving bikes.