Instarinse:

disposable to reusable

The brief

Theo and Rory came to us with a high-level working prototype. Their project enables users to rinse their reusable coffee cup in under 15 seconds using minimal energy and water. For example a user would enter a coffee shop and ask if a staff member could wash/rinse out their already used flask. The developed product would increase the efficiency of baristas and turnover of orders, as the customer would rinse their cup themselves.

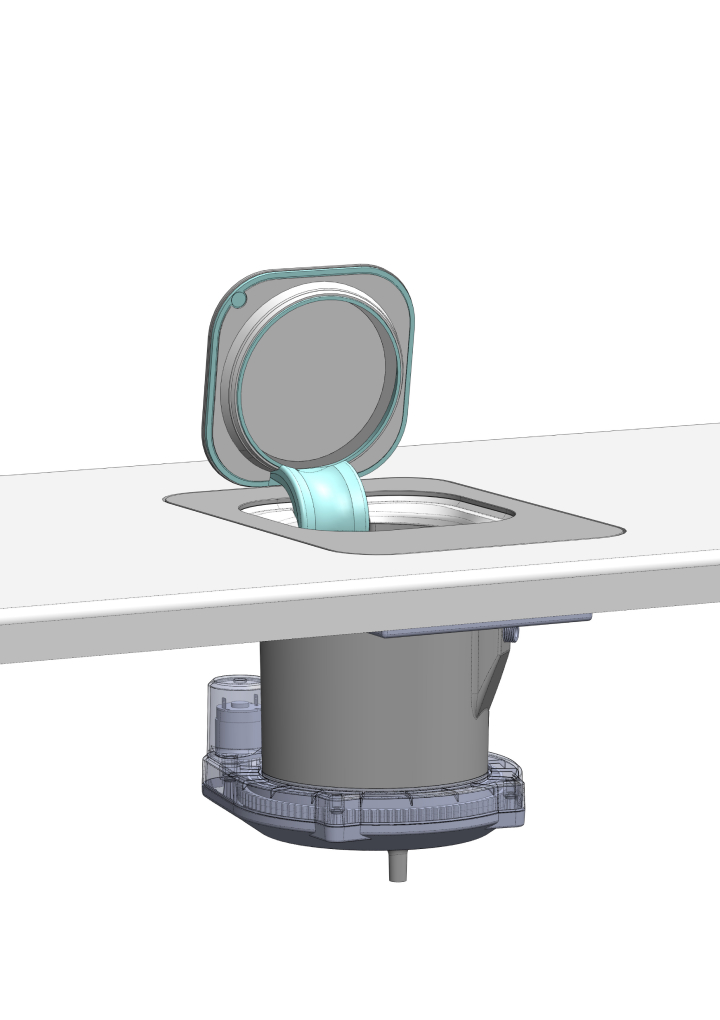

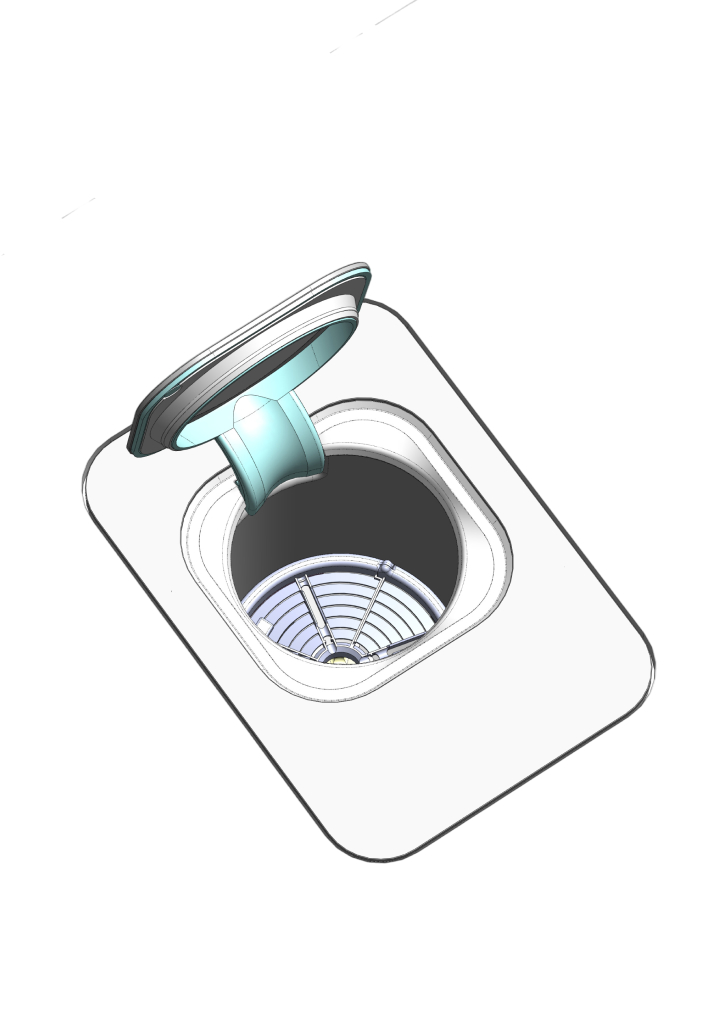

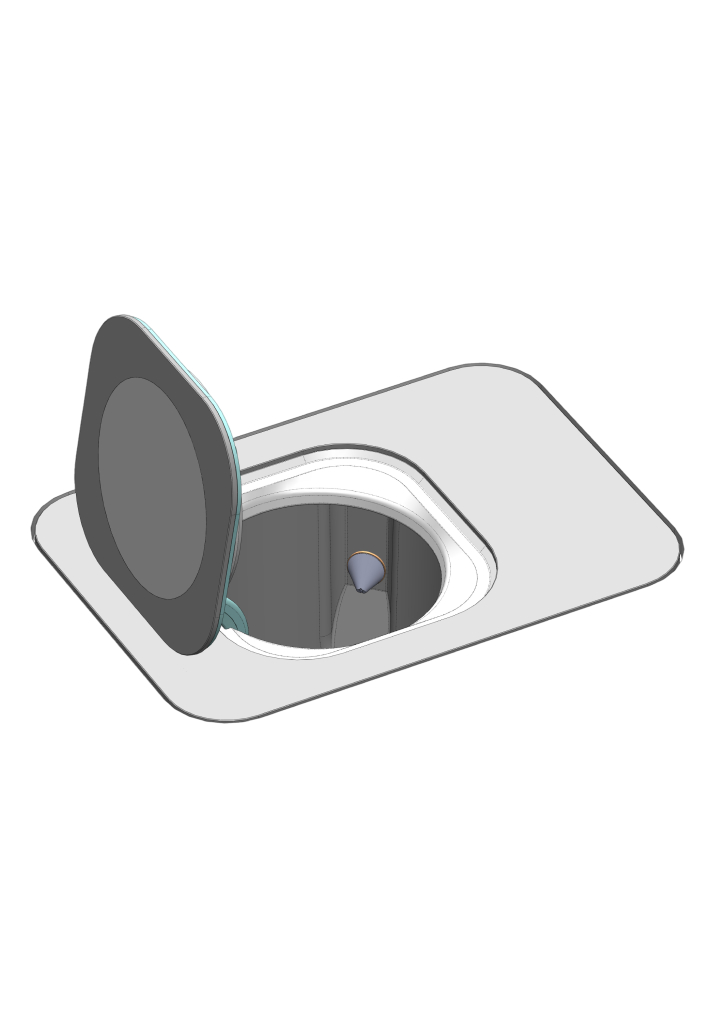

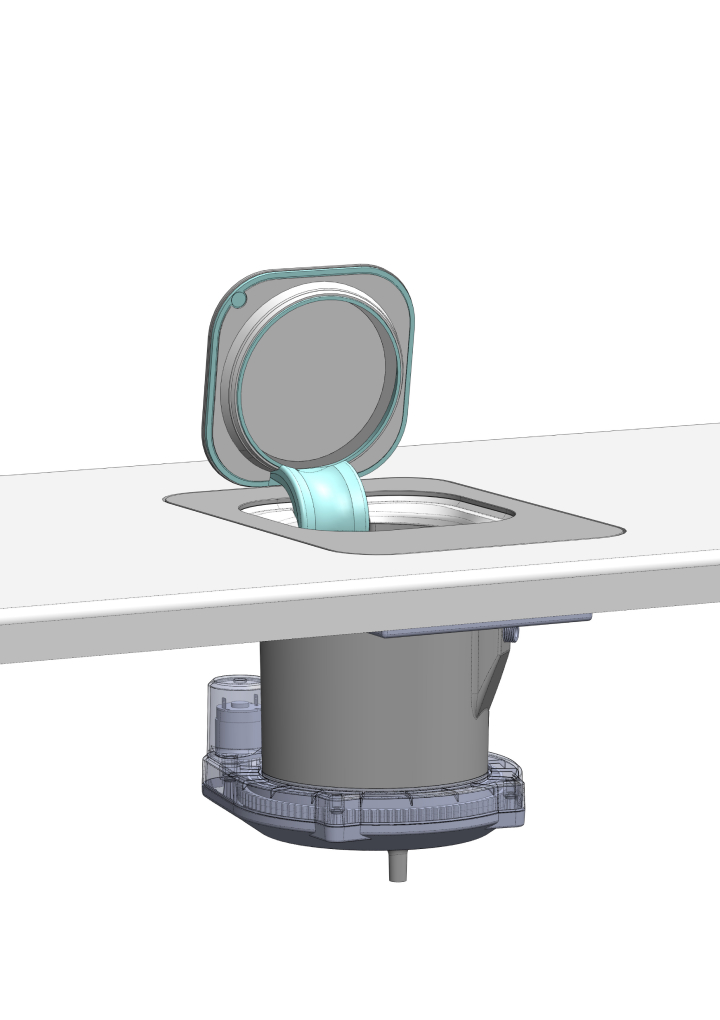

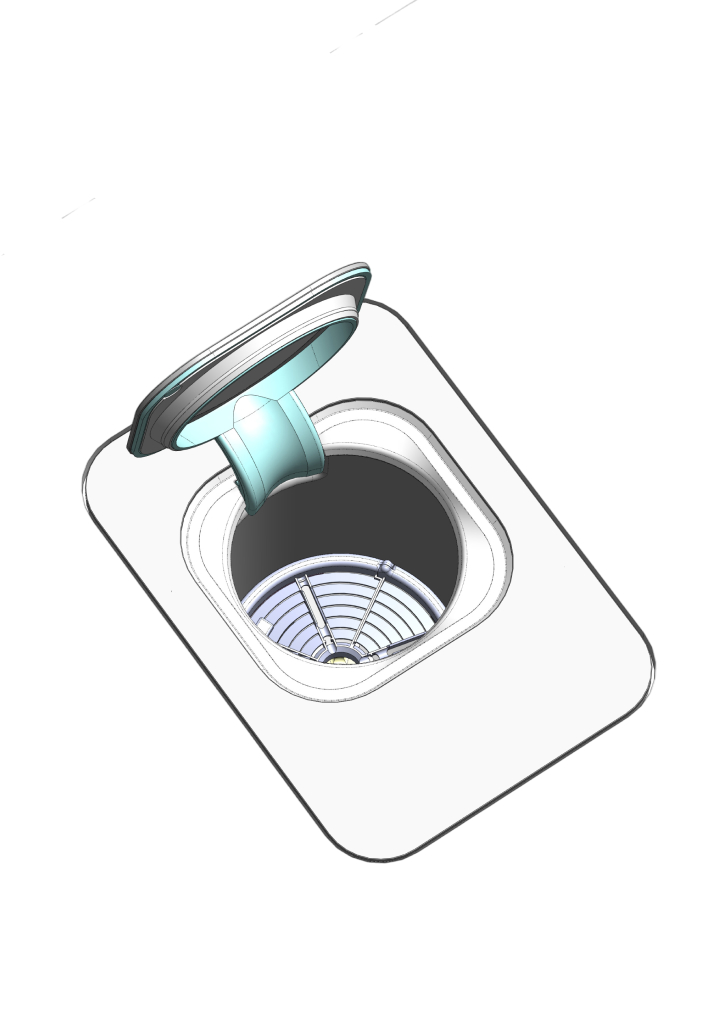

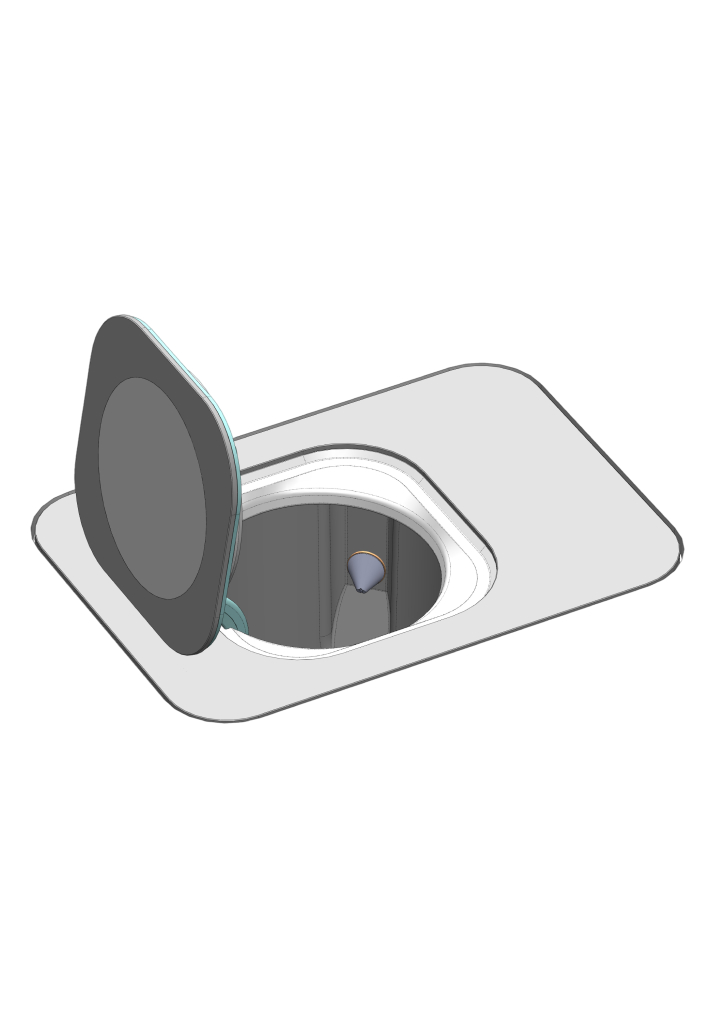

The product consisted of; high pressure water and steam jets for cleaning, a motor-powered lid, turntable to ensure even clean around the cup.

Their working prototype was presented to potentially interested parties and received great feedback with interest from major partners within the food & drinks market.

As a result of their initial success, they needed help with two areas: experience in making robust and commercially viable product, and an external design resource to speed up their time to market.

The bang

Initially, we reviewed their working prototype and design files. We assessed many aspects including user interaction, component durability, part selection, engineering and manufacturing challenges.

Following our review, we completed an engineering design phase which included all components, but with an emphasis on motor selection, control & mounting used for lifting up the glass lid, and also a central rotating table drive mechanism which was integral to the quality of the clean. We developed all parts and produced 3d CAD for the full assembly.

We then worked with our supplier network to produce a prototype batch of 5pcs. This was to ensure all changes had a positive effect and enabled the reduction of risk prior to production tooling.

The result

Following the successful prototype delivery Theo and Rory continued working with suppliers to start production tooling. Their market and business grew and they worked closely with some of their most trusted clients. instarinse® enabled sites to move away from disposables within weeks, saving significant costs on paper cups, energy and water.

They are now partnered with AGGORA and units are in production with live nationwide services.

Lava Labs and AGGORA are delivering instarinse®, the complete solution for organisations ready to move beyond disposables and into the sustainable future.

Instarinse:

disposable to reusable

The brief

Theo and Rory came to us with a high-level working prototype. Their project enables users to rinse their reusable coffee cup in under 15 seconds using minimal energy and water. For example a user would enter a coffee shop and ask if a staff member could wash/rinse out their already used flask. The developed product would increase the efficiency of baristas and turnover of orders, as the customer would rinse their cup themselves.

The product consisted of; high pressure water and steam jets for cleaning, a motor-powered lid, turntable to ensure even clean around the cup.

Their working prototype was presented to potentially interested parties and received great feedback with interest from major partners within the food & drinks market.

As a result of their initial success, they needed help with two areas: experience in making robust and commercially viable product, and an external design resource to speed up their time to market.

The bang

Initially, we reviewed their working prototype and design files. We assessed many aspects including user interaction, component durability, part selection, engineering and manufacturing challenges.

Following our review, we completed an engineering design phase which included all components, but with an emphasis on motor selection, control & mounting used for lifting up the glass lid, and also a central rotating table drive mechanism which was integral to the quality of the clean. We developed all parts and produced 3d CAD for the full assembly.

We then worked with our supplier network to produce a prototype batch of 5pcs. This was to ensure all changes had a positive effect and enabled the reduction of risk prior to production tooling.

The result

Following the successful prototype delivery Theo and Rory continued working with suppliers to start production tooling. Their market and business grew and they worked closely with some of their most trusted clients. instarinse® enabled sites to move away from disposables within weeks, saving significant costs on paper cups, energy and water.

They are now partnered with AGGORA and units are in production with live nationwide services.

Lava Labs and AGGORA are delivering instarinse®, the complete solution for organisations ready to move beyond disposables and into the sustainable future.

Instarinse:

disposable to reusable

The brief

Theo and Rory came to us with a high-level working prototype. Their project enables users to rinse their reusable coffee cup in under 15 seconds using minimal energy and water. For example a user would enter a coffee shop and ask if a staff member could wash/rinse out their already used flask. The developed product would increase the efficiency of baristas and turnover of orders, as the customer would rinse their cup themselves.

The product consisted of; high pressure water and steam jets for cleaning, a motor-powered lid, turntable to ensure even clean around the cup.

Their working prototype was presented to potentially interested parties and received great feedback with interest from major partners within the food & drinks market.

As a result of their initial success, they needed help with two areas: experience in making robust and commercially viable product, and an external design resource to speed up their time to market.

The bang

Initially, we reviewed their working prototype and design files. We assessed many aspects including user interaction, component durability, part selection, engineering and manufacturing challenges.

Following our review, we completed an engineering design phase which included all components, but with an emphasis on motor selection, control & mounting used for lifting up the glass lid, and also a central rotating table drive mechanism which was integral to the quality of the clean. We developed all parts and produced 3d CAD for the full assembly.

We then worked with our supplier network to produce a prototype batch of 5pcs. This was to ensure all changes had a positive effect and enabled the reduction of risk prior to production tooling.

The result

Following the successful prototype delivery Theo and Rory continued working with suppliers to start production tooling. Their market and business grew and they worked closely with some of their most trusted clients. instarinse® enabled sites to move away from disposables within weeks, saving significant costs on paper cups, energy and water.

They are now partnered with AGGORA and units are in production with live nationwide services.

Lava Labs and AGGORA are delivering instarinse®, the complete solution for organisations ready to move beyond disposables and into the sustainable future.